Navigating Transformer Choices: Oil-Immersed vs. Dry-Type for Optimal Performance in 2025

Navigating Transformer Choices: Oil-Immersed vs. Dry-Type for Optimal Performance in 2025

In the world of electrical engineering, transformers are the unsung heroes powering everything from urban skyscrapers to remote industrial sites. But when it comes to selecting the right type—oil-immersed or dry-type—the decision can make or break efficiency, safety, and sustainability. Drawing from international standards like IEC 60076 (Power Transformers) and IEEE C57.12.00 (General Requirements for Liquid-Immersed Distribution, Power, and Regulating Transformers), as well as practical insights from industry experts, let's break down the ideal scenarios for each, along with some common pitfalls to avoid.

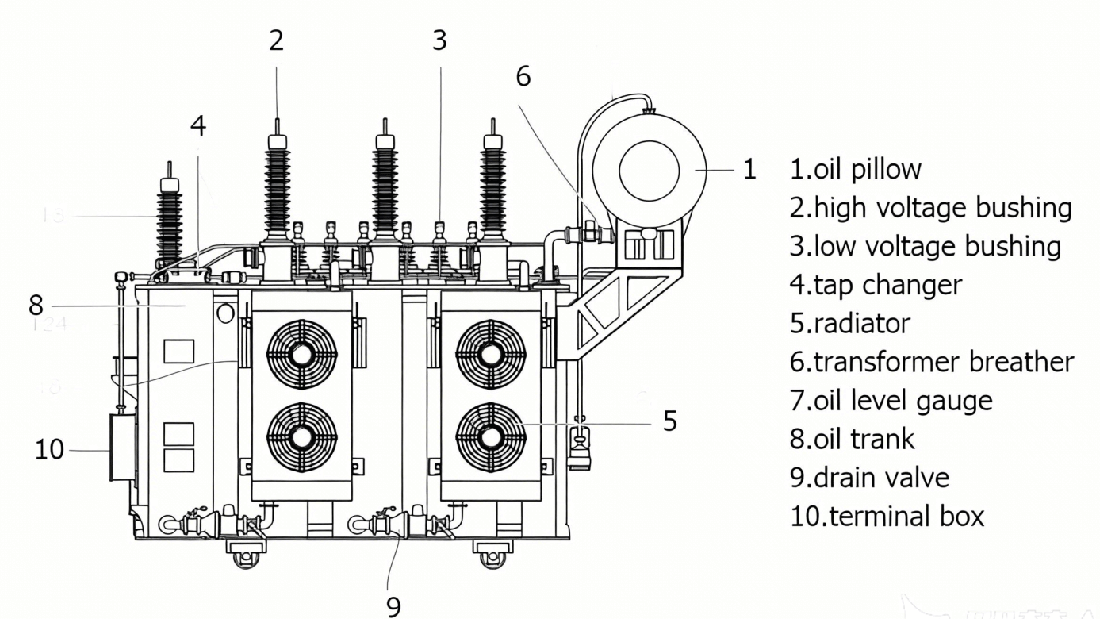

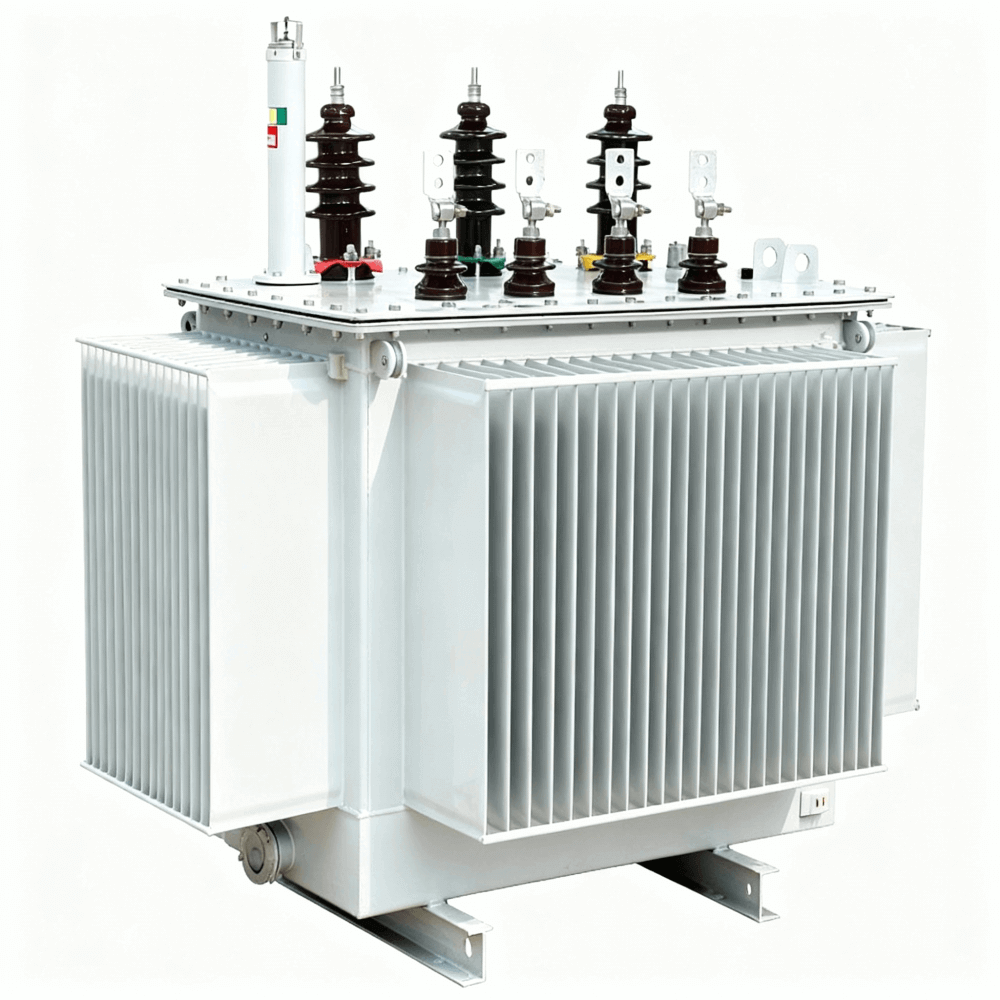

When Oil-Immersed Transformers Shine: High Capacity, Superior Cooling, and Cost Efficiency

• Superior Heat Dissipation: Oil's natural convection and optional forced cooling (e.g., ONAN/ONAF systems outlined in IEC standards) provide exceptional thermal management. This is crucial in hot climates or continuous high-load scenarios, such as data centers with fluctuating demands or oil refineries. Studies from the IEEE Transformer Committee highlight how oil circulation can extend lifespan by 20-30% compared to air-cooled alternatives.

• Cost-Effective Choice: From a lifecycle perspective, oil-immersed units are often 20-40% cheaper upfront, per cost analyses in IEC technical reports. Maintenance is straightforward—oil testing for dissolved gases (per IEEE C57.104) catches issues early—making them budget-friendly for outdoor installations where space isn't a constraint. They're perfect for rural utilities or industrial parks prioritizing ROI over premium features.

In essence, if scalability and value drive your decisions, oil-immersed transformers align with standards emphasizing reliability in expansive, high-power setups.

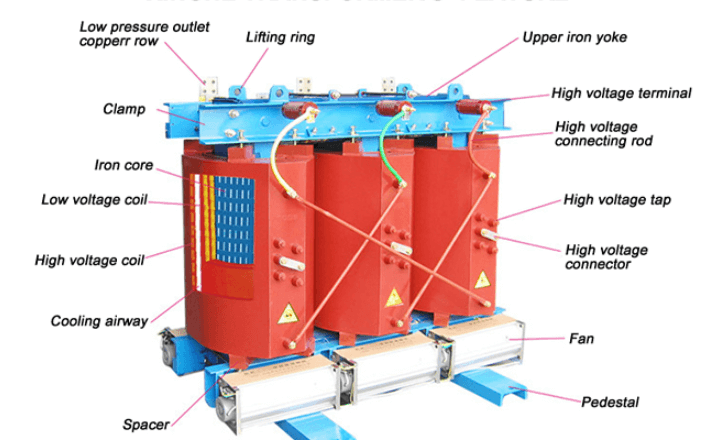

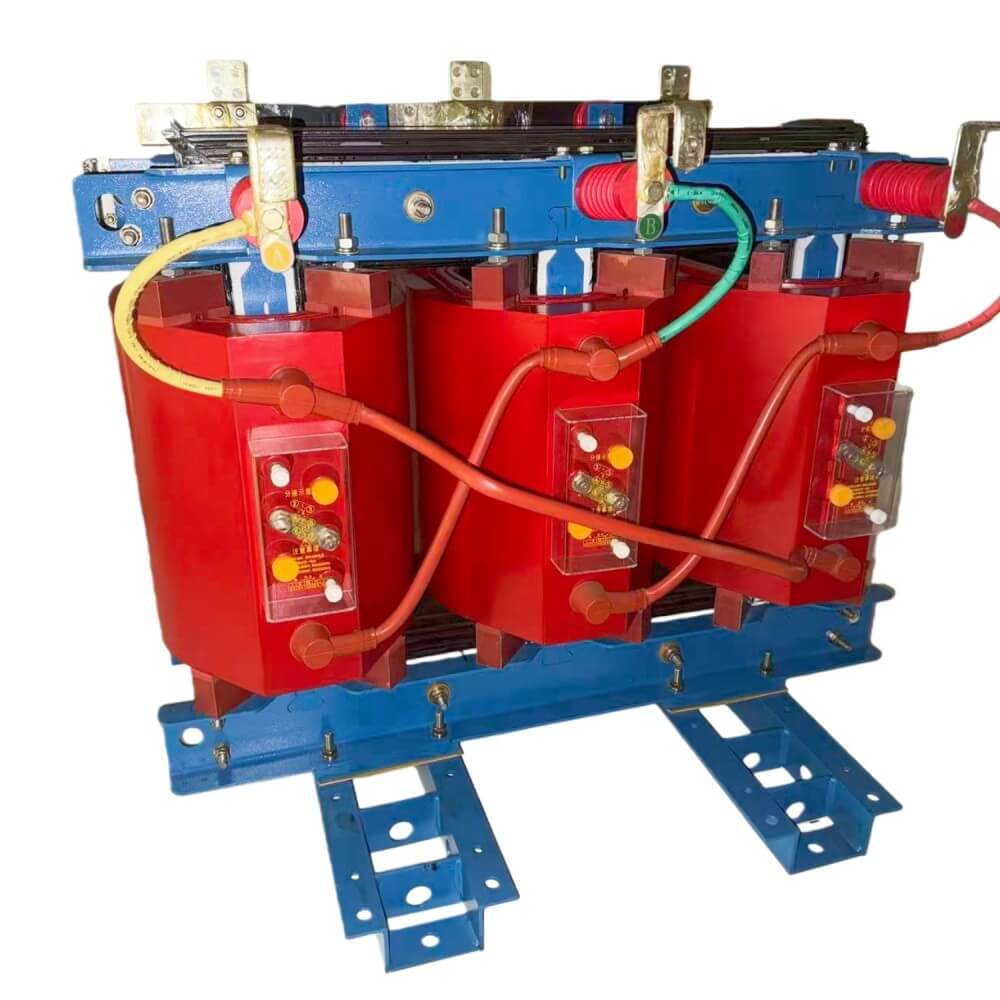

Dry-Type Transformers: Prioritizing Fire Safety, Indoor Flexibility, and Environmental Sustainability

• Indoor and Space-Constrained Environments: Compact and maintenance-free, dry-types fit seamlessly into basements, rooftops, or urban high-rises without needing oil containment pits. IEEE guidelines recommend them for installations near people or sensitive equipment, like commercial offices or metro stations, where noise and vibration must be minimal.

• Environmental Advantages: Eco-conscious? Dry-types eliminate oil leaks and disposal hassles, aligning with EU REACH regulations and IEC's push for sustainable materials. They're recyclable and produce lower greenhouse gas emissions over their lifecycle, making them a staple in green-certified projects like LEED buildings or data centers aiming for net-zero goals.

For scenarios where safety and eco-friendliness outweigh raw power, dry-type transformers deliver compliance and peace of mind.

Common Misconceptions: Don't Fall for These Traps

Another pitfall: Assuming oil-immersed are "outdated" or always risky. Modern bio-based oils (per IEC 60076-14) mitigate environmental concerns, and advanced monitoring tech makes them as reliable as ever. Conversely, underestimating dry-type cooling needs in humid areas can lead to overheating—always factor in ambient conditions per standards.

The key? Conduct a site-specific risk assessment, considering load profiles, local codes, and total ownership costs. Tools like IEEE's transformer selection guides can help quantify trade-offs.

What are your experiences with these transformers? Have you encountered a scenario where one outperformed the other unexpectedly? Share in the comments—let's spark a discussion!